Innovations - April

Electric valve actuator achieves CSA Class 1, Div. 2 hazardous location certification

Curtiss-Wright’s Actuation Division’s new Exlar Tritex® electric valve actuator (EVA) has achieved CSA Class 1, Div. 2 (C1D2) Hazardous Location certification. It also outperformed U.S. oil and gas producers’ expectations for rugged field test operations in Texas, Oklahoma and New Mexico.

The Tritex EVA answers the demand for an efficient, high-speed solution while meeting the Methane Emissions Reduction Program (MERP) and Quad-O zero-emissions regulations in the oil and gas industry.

The Tritex EVA is environmentally friendly and efficient with a powerful, compact system integrating a servo drive, motor and roller screw actuator to achieve extreme life, speed and accuracy. Combining the simplified actuation system with Modbus RTU communications enables producers to have remote operation and monitoring with fewer components when compared with pneumatic systems.

The electric Tritex EVA was under field test throughout 2023. The field trial units remain successfully in service, proving the ruggedness of this new technology. Exlar is a business unit of Curtiss-Wright’s Actuation Division.

For more information about the Tritex EVA or the Curtiss-Wright Exlar business, visit www.exlar.com.

New control cabinet IPC supports growing requirements for adaptive manufacturing, machine-learning

The C6675 control cabinet industrial PC (IPC) from Beckhoff supports growing requirements for adaptive manufacturing, machine-learning (ML) and other transformational applications. Building on proven Beckhoff technologies, the new IPC meets these demands through its robust ATX motherboard and high-performance GPU cards.

With properties typical of an industrial server, the C6675 (FIG. 1) consolidates numerous complex automation tasks previously handled by separate controllers into one high-powered device. The new control cabinet IPC is equipped with components of the highest performance class based on latest-generation Intel® Celeron®, Pentium® or Core™ i3/i5/i7 platforms on an ATX motherboard designed and assembled by Beckhoff.

FIG. 1. The C6675 control cabinet industrial PC (IPC) from Beckhoff supports growing requirements for adaptive manufacturing, machine-learning (ML) and other transformational applications.

By leveraging the rugged housing, heat dissipation and power supply tech from the C6670 series, the new controller enables the use of additional high-performance graphics cards, among other benefits. This makes it possible to implement even computationally intensive ML or machine vision applications in industrial environments.

The C6675 offers numerous available expansion slots, including two PCIe-x1, two PCIe-x4, one PCIe-x16 and two PCI for full-length plug-in cards with a total of up to 300 W power. Two removable SSD or hard disk frames, in conjunction with the on-board RAID controller, form a RAID-1 system with two mirrored hard disks or SSDs. This ensures high data security, so hard disks or SSDs can easily be replaced during operation.

For more information, visit C6675 control cabinet IPC.

Positive displacement pump optimizes cost and efficiency

Waukesha Cherry-Burrell® (WCB), a brand of SPX FLOW, has released the Universal® 2 ND positive displacement pump (U2 ND) series designed with industrial users in mind. The pumps offer the quality and durability the Waukesha Cherry-Burrell brand is known for while optimizing cost and suitability for the industrial market.

The U2 ND series significantly expands the WCB pump range, aimed at enhancing reliability and performance across industrial applications while outperforming other pump styles, such as industrial lobe, gear or progressive cavity pumps.

The design features improvements uniquely suited for industrial applications, including:

- Total cost of ownership: The pump ensures a long running life, given its robust construction materials and designs tailored for each application. Because of its high volumetric efficiency, the pump can be used to dose fluids, eliminating the need for an additional metering pump.

- Efficiency: The U2 ND pump reduces slip, which occurs when fluids move backward from the liquid flow due to internal clearances. Lower slip means more efficiency, reducing the need for higher horsepower motors. Also, the series can process fluids over longer spans due to its high-pressure capability, which reduces the need for multiple pumps in these applications.

- Reliability: WCB is a proven and trusted global brand dating back to the 1880s. The pumps are made with durable, corrosive-resistant materials compatible with industrial environments. A robust design, equipped with industrial flanges or sanitary fittings, ensures manufacturers can choose the configuration to meet their needs.

Additionally, an extensive sales channel and domestic manufacturing footprint support this pump series, enabling quick deliveries on standardized parts across the entire Universal pump product line. The U2 ND series is complemented by the Universal Industrial 5000 series, which is tailored for users who require original equipment manufacturer (OEM) seals for their industrial pumping operations.

SPX FLOW’s product offering is concentrated in process technologies that perform mixing, blending, fluid handling, separation, thermal heat transfer and other activities that are integral to processes performed across a wide variety of industrial markets. SPX FLOW has operations in more than 25 countries and sales in more than 140 countries.

To learn more about the U2 ND positive displacement pump series, visit www.spxflow.com/waukesha-cherry-burrell/products/universal-2-nd-series-positive-displacement-pumps/

Accurate and reliable oxygen measurements for safe continuous operations

Yokogawa Corporation of America has released its Extractive Tunable Diode Laser Spectrometer TDLS8220 (FIG. 2), a new generation OpreX™ Analyzer product. This product joins Yokogawa’s existing lineup that includes the in-situ TDLS8000 and probe type TDLS8100/TDLS8200.

FIG. 2. Yokogawa Corporation of America’s Extractive Tunable Diode Laser Spectrometer TDLS8220 unit.

Built upon Yokogawa’s second generation of TDLS analyzers with improved reliability, quick response time and reduced maintenance, the TDLS8220 is a direct replacement for the first-generation TDLS220.

The original platform of the TDLS200 was developed due to the U.S. Department of Energy (DOE) program, “In-situ sensors for the chemical industry.” The product was released in 2005 and achieved success in many different process applications and in a variety of industries, with > 1,500 units sold worldwide.

The TDLS8220 is being introduced to complement Yokogawa’s existing TDLS product lineup to satisfy the need for extractive oxygen measurements where in-situ or probe-type installations are not applicable and where traditional technologies fall short.

The TDLS8220 laser module and detector module are now encompassed in one board set, but still retain a reference cell for improved reliability of absorption peak detection. In addition, the auto gain function automatically optimizes detection sensitivity during dynamic process events. Due to the non-contact measurement, sample handling system upsets or failures will not damage the analyzer sensor. The TDLS8220 plays a key role in ensuring accurate and reliable oxygen measurements for safe continuous operation.

The unique flow cell design features a tube-in-shell construction that allows tight temperature control of extractive samples at the desired set point. The analyzer does not require consumables, and solid-state technology eliminates the need for routine calibration. The TDLS8220 supports field serviceability with onboard diagnostics and 50 d of data and spectral storage to identify and correct minor issues before they turn into serious problems.

Major target markets include the oil and gas, petrochemicals and specialty chemicals segments, with applications ranging from marine vapor recovery and oxygen monitoring in ethylene oxide production, to safety related limiting oxygen concentration (LOC) measurement and other process oxygen measurements.

For more information, visit the TDLS8220 webpage.

Complete high-pressure marine pump unit for LNG fuel

High-pressure liquefied natural gas (LNG) engines offer lower fuel consumption and significantly reduced methane slips. This is driving a surge in demand for crucial components for LNG high-pressure fuel supply systems, which Svanehøj is now ready to meet.

Drawing from extensive expertise in cryogenic solutions, the Danish marine pump specialist has developed a high-pressure fuel pump unit with a drive system and three combined cold ends designed for optimal flow and longer service intervals. The new solution is called HPP Triplex Unit.

It is evident that more integrators of fuel gas supply systems are taking on a progressively substantial role in designing fuel supply systems, especially for LNG-powered vessels. Therefore, they increasingly require critical components specially designed to operate under extremely low temperatures and high pressures. Based on decades of experience in low-pressure fuel and cargo pumps for LNG, Svanehøj made a strategic decision to extend its scope and include a larger part of the LNG fuel supply system by developing a high-pressure pump unit, exclusively designed for maritime purposes.

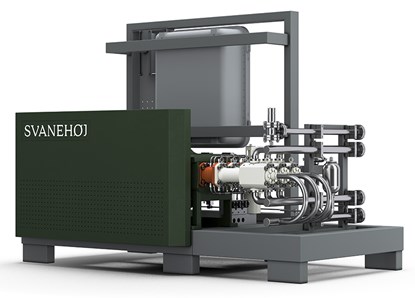

Svanehøj has designed the HPP Triplex Unit (FIG. 3) to meet the maritime industry's demands for leak-free critical components with a long service life. The cold end includes an innovative low-pressure sealing arrangement that reduces friction, ensuring longer service intervals. To further reduce maintenance costs, Svanehøj has developed a cartridge solution for swift sealing replacement. To ensure high efficiency and low-pressure drop, Svanehøj has also incorporated a new inlet valve design.

FIG. 3. The Svanehøj HPP Triplex unit is a triplex type high-pressure piston pump for LNG, with a belt drive system, installed on a skid for easy transportation and installation.

As part of its ESG strategy, Svanehøj is committed to directing 95% of its R&D investments at solutions and products that support the energy transition in hard-to-abate sectors. This includes pumps and equipment for carbon capture, Power-to-X and LNG. In recent years, Svanehøj has invested significantly in new products and services for the LNG segment, including a new submerged fuel pump, launched in 2022, and the 2023 acquisition of the U.S.-based specialist in service and overhaul of LNG pumps, Complete Cryogenic Services (CCS).

In an ideal scenario, all ships would immediately begin operating on carbon-free fuels. However, it will take several years to establish an infrastructure to meet the need for liquid renewable energy. Transition fuels are essential for a successful energy transition, and natural gas is by far the best option, offering significant environmental benefits.

The uptake of LNG has been high in recent years, especially among new builds. According to the DNV database for alternative fuels, there are now 431 LNG-powered ships in operation and another 539 ships on order, bringing the total count close to 1,000 vessels. In 2021 and 2022 alone, 462 LNG-fueled ships were ordered, and in the first 9 mos of 2023, a further 104 ships were added to the global order book.

The HPP Triplex unit is a triplex type high-pressure piston pump for LNG, with a belt drive system, installed on a skid for easy transportation and installation. Features include:

- 3 pcs. of cold ends

- ATEX motor downrated for VFD operation

- Media: LNG

- Capacity: 11.5 l/min–72 l/min (0.7 m3/hr–4.3 m3/hr)

- Inlet pressure: 7 bar–14 bar

- Operational design pressure: 350 bar

- Maximum working pressure: 380 bar

- Minimum operation temperature: –163°C

- Unit dimensions: 3,000 mm x 1,390 mm x 1,100 mm.

For more information about the HPP Triplex Unit, visit https://www.svanehoj.com/solutions/fuel-gas-solutions/hpp-triplex-pump-unit/

Comments