ISO/ASME-compliant composite pipe repair system

Pipelines, especially those of large diameter, can efficiently transport large volumes of liquids and gases over long distances. Operating over long distances through various landscapes, environments and conditions, pipelines can be subject to internal and external effects from numerous factors. Differences in height cause internal pressure fluctuations, while changes in temperature cause the pipe material to expand and contract; from these behaviors, pipelines are subjected to physical loads such as bending, shear, torsion and fatigue. At the same time, the inner walls of pipes can be exposed to corrosion and chemical attack, depending on the chemicals involved in the media. Similarly, under conditions of inadequate protection, pipes are also subject to external corrosion (FIG. 1).

|

|

FIG. 1. The in-field application of the pipe repair technologya on a corroded pipeline. |

These effects, acting alone or in combination, can cause damage to the pipe wall in the form of metal loss and eventually lead to through-wall defects and leakage problems (FIGS. 2–4). Leaks can also have disastrous consequences (i.e., shutdowns and environmental impacts). For this reason, it is incumbent on facility owners and operators to take proactive precautions to prevent the worst from happening.

|

|

FIG. 2. Damaged pipeline after suffering from corrosion under insulation (CUI). |

|

| FIG. 3. After rebuilding the pipe to its original profile using the author’s company’s two-part repair compositeg, several wraps of the hybrid fibere were applied. |

|

| FIG. 4. The pipe repair before the removal of the release film. |

In the past, the repair of deteriorated pipework involved the welding of plates and sleeves, the use of bespoke clamps or the partial replacement of the faulty section. In recent years, however, the use of polymeric composite materials for the repair of pipes has gained global support and interest. The main reasons for this include: the composite repair can be based on engineered structural calculations in accordance with internationally recognized standards; unlike welding, it is a safe cold process that can be carried out in areas where hot work is prohibited; and it can be carried out at lower cost and provide long repair life sufficient to be taken as a permanent repair.

This paper describes the author’s company’s pipe repair technologya, including details of various tests conducted on the system to comply with both International Organization for Standardization (ISO) 248171 and American Society of Mechanical Engineers (ASME) PCC-2 (Article 401)2, the two major international standards for composite pipe repair.

Composite pipe repair technology. The proprietary pipe repair technologya is based on a polymer-based composite of epoxy resin and reinforcing fibers, using a wet-wrapping technique in which the resin-impregnated reinforcing fibers are wrapped directly around the pipe defect and cured.

Two material properties are key to the development of composite materials for the repair of wall thinning and leakage defects in pipes: mechanical strength and stiffness. Mechanical strength depends on the maximum tensile stress that a material can withstand without failure and is determined from its tensile strength. Stiffness, on the other hand, refers to the elastic deformation of a material when a force is applied and is defined by the Young's modulus (also known as tensile modulus or modulus of elasticity). In the case of polymeric composites, the mechanical strength and stiffness depend to a large extent on the properties of the reinforcing fiber. The resin is responsible for transferring the load between the reinforcing fibers. The success of a composite repair also depends on the adhesive strength of the resin, as it must be integrated with the pipe substrate.

In the development of the pipe repair technologya, several combinations of resins and reinforcing fibers were considered. In the end, a two-component epoxy resin with 100% solids content—consisting of a phenolic novolac base (main agent) and an amine solidifier—was chosen. The main reason for this was the emphasis on the fact that epoxy resins can achieve better adhesion and mechanical strength compared to other functional polymer groups, including polyurethanes, methacrylates, alkyds, vinyls and polyesters. The possibility of forming highly cross-linked polymer matrices, which are the basis for excellent heat and chemical resistance, should also be supplemented as one of the reasons for concluding that phenolic novolac epoxy resins are the best choice.

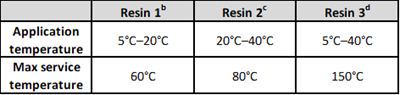

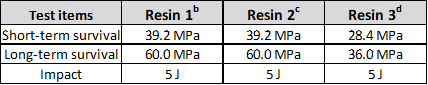

In general, epoxy resins are slow to cure at low temperatures; however, when heat is applied, the reaction is activated and the resin cures in a shorter time. Considering the temperature conditions at the time of application—which tend to be affected by climatic differences—two types of resin were initially developed (Resin 1b and Resin 2c), followed by Resin 3d with improved heat resistance (TABLE 1). Today, three different types of resin are available, allowing the user to select the most suitable material depending on the temperature conditions.

|

|

TABLE 1. Usable temperature ranges for each resin |

The most suitable reinforcing fiber material was selected based on the material's mechanical strength and stiffness, as well as its workability (cutting, resin impregnation, onsite handling, etc.). After carefully considering the pros and cons of each material, it was decided to use a hybrid fibere, a combination of carbon fiber and glass fiber, which is produced by the author’s company to be an optimized reinforcement fiber sheet for the pipe repair technologya. The hybrid fibere reinforcing sheet has a two-layer construction, with carbon fiber on the front and glass fiber on the back, to maximize the benefits of both fibers and to achieve the most efficient distribution and arrangement in terms of physical properties and workability—the glass fiber and epoxy resin layer are designed to act as an insulator to prevent corrosion currents from flowing through the conductive carbon fiber. The reinforcing fiber sheets are available in several different widths to accommodate different pipe diameters, with wider sheets being particularly useful for special geometries such as bends, tees, flanges and reducers, as well as the walls and roofs of large storage tanks.

After the resin-impregnated reinforcing fibers have been wrapped around the pipe, a special consolidating filmf is used to hold the repair in place until the resin has cured. Once the resin has cured, the film can be easily removed.

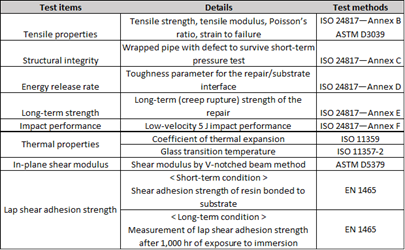

Compliance with standards. The composite repair of pipework requires a high degree of reliability, especially in the case of high-pressure piping systems or for pipes carrying hazardous media. For this reason, rigorous third-party and in-house testing is carried out to demonstrate compliance with a series of requirements set out in ISO 24817 and ASME PCC-2. For the tests aimed at assessing the mechanical properties of the materials, plate specimens made of reinforcing fiber and each resin were used. Conversely, in the pressure resistance test aimed at evaluating system durability, a short pipe spool with pseudo-defects of the specified dimensions was repaired with the system, followed by a pressure resistance test for confirmation. A summary of each test is given in TABLE 2.

|

|

TABLE 2. Test items and test methods |

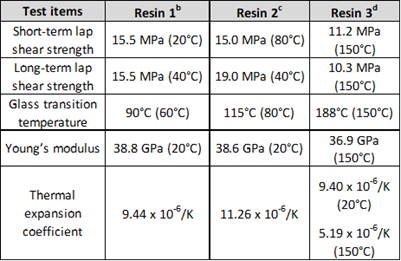

Test results and verification. TABLE 3 shows some results of the physical property tests. The curing temperatures of the specimens are in parenthesis.

|

|

TABLE 3. Composite properties assessment results |

In the tensile shear bond strength test, the bond strength of the resins is measured in two ways (both using carbon steel as the adherent):

- Cured for 7 d at specified temperature conditions (short-term condition)

- Immersion in water for 1,000 hr at specified temperature conditions (long-term condition).

The comparison of the results of the low- and high-temperature tests is intended to see the effect of temperature changes on the adhesive strength of the resins. The results comply with the requirements of ISO 24817 in two respects:

- The tensile shear bond strength of each resin is > 5 MPa for short- and long-term conditions.

- For each resin, the long-term values are at least 30% of the short-term values.

The glass transition temperature (Tg) is the temperature at which a polymer material begins to soften as it is heated. It is a common phenomenon for thermoplastics and its value is often referred to in assessing the thermal properties and thermal resistance of resin-based repair techniques. When the resin is heated while it is curing, the density of the cross-linking increases and the glass transition temperature rises. When Resin 1b is cured at 60°C, Resin 2c at 80°C and Resin 3d at 150°C, the glass transition temperatures are 90°C, 115°C and 188°C, respectively (see TABLE 3).

Piping systems under pressure are subject to the Poisson effect. Due to the circumferential stresses occurring inside the pipe, the diameter of the pipe increases slightly; however, at the same time, a contraction occurs in the axial direction and the pipe becomes shorter. Therefore, a Poisson's ratio close to the value of the pipe is required for the composites to be a suitable material to restore the mechanical strength of the pipelines. The Poisson's ratio of the pipe repaira material (FIG. 5) is close enough to that of steel. This means that when a typical steel pipe is subjected to compressive or tensile loads, the accompanying pipe repaira reacts similarly to the base metal.

|

|

FIG. 5. The author’s company’s pipe repair technologya being applied. |

Young's modulus (tensile modulus) is a measure of the stiffness of a material, and the pipe repaira materials have a high Young's modulus of 37 GPa–39 GPa (i.e., the repair will have good stiffness and bending moment). From a practical point of view, when assessing the performance of a composite pipe repair, it is reported that a standard modulus of elasticity of 6,895 MPa or higher is desirable3—the values of the pipe repaira materials are well above this. Conversely, considering that the Young's modulus of ordinary steel is about 200 GPa, the pipe repaira materials, which have about one-fifth, are far more elastic than steel. In this sense, it can be said that pipe repair technologya has excellent elasticity and can easily follow the movement of the base metal.

The thermal expansion coefficient of a solid material indicates the extent to which its length and volume change when subjected to a change in temperature under constant pressure conditions. Piping, which is subjected to a variety of operating conditions, generally undergoes repeated expansion and contraction due to temperature changes. Therefore, composite materials used to restore the mechanical strength of pipe materials must also be able to cope with thermal strain. The linear expansion coefficient of the pipe repair materialsa cured at ambient temperature are between 9.40 and 11.26 x 10-6/K, which is close to that of ordinary steel (11-12.5 x 10-6/K).4 This means that the stress effect (thermal strain) on the adhered surface caused by the difference in thermal expansion between the composite materials and the base metal is minimal.5

TABLE 4 shows the conditions for durability testing of the pipe repaira composite materials.

|

| TABLE 4. Testing conditions for composite performance |

The short-term pressure test evaluates the performance of the pipe repair technologya against wall thinning defects (no penetration). The objective is to determine the maximum level of wall thinning that can be repaired. The test is carried out on a short carbon steel spool with a pseudo-defect (wall loss) of a specified size. The repair is designed to restore the yield strength of the original pipe wall. The test pressure was calculated as the yield pressure of the test spool in its original sound condition (test pressures indicated in TABLE 4). The difference in test pressure between Resins 1b and 2c and Resin 3d is due to the different test spools used. All the resins passed the test and the results demonstrate that the repair conforms to the design specification and can restore the durability of the pipe material.

The long-term pressure test also evaluates the performance of the pipe repair technologya against thin-wall defects. Here, the durability of the repair is assessed after 1,000 hr of sustained loading by maintaining the pipe internal pressure at a constant level (test pressures indicated in TABLE 4). As a result, no cracks, delamination or any other degradation was observed and the test was therefore deemed a pass.

The impact endurance test examines the effect on the repair of a low-velocity 5 J impact, simulating a tool drop such as a spanner being dropped on the repair. The objective of this test is to determine the minimum thickness of the repair layer where external impact is concerned. In accordance with ISO 24817—Annex F, an impact of 5 J was applied to the pipe repair by dropping a weight from a height of 1 m, followed by a pressure test. The results showed that there was no difference between the measured and calculated energy release rates, and it was concluded that this level of impact did not affect the integrity of the pipe repair systema.

Requirements for the pipe repair applicationa. The repair design of the pipe repair technologya is determined by strength calculations based on actual defective conditions of pipes in accordance with the ISO/ASME standards, which also consider factors such as surface preparation method, pipe geometry, environmental conditions, operational/design pressures, etc. The repair is then carried out following the design; however, certain conditions must be adhered to during the application.

First, to ensure the quality of the work, all pipe repaira installers must attend and pass a validated training course. The course includes a practical test (as well as a theory exam) in which participants are asked to repair a pipe spool with a simulated defect, which must then pass a certain pressure test.

As a strict rule, a compliant repair must always be conducted by trained installers. The ISO/ASME standards define repair classes from Class 1 to Class 3. Class 1 is for low-specification duties with the least critical conditions, such as a pressure of < 2 MPa and a temperature of < 40°C—since this is for systems that do not relate directly to personnel safety, the repair jobs can be handled by installers alone. Class 2 and 3 repairs, however, involve more critical scenarios (e.g., higher pressure and temperature conditions as well as systems transporting hazardous fluids)—in those cases, therefore, the work must be supervised by a certified supervisor who has completed a higher level of training. Periodic annual renewal of qualifications is also compulsory for the installers and supervisors to ensure they maintain and improve their skills after certification.

All inspection results, including environmental measurements, surface roughness achieved by surface preparation conducted, batch numbers of products used, and resulting repair thickness, are recorded in quality assurance/quality control (QA/QC) documents of each project. This information will be collected on all projects, including information on the installer/supervisor involved.

After use in service, the repair technologya repairs can be revalidated or decommissioned upon reaching its design lifetime, depending on the decision made by the asset owner.

The repair solutiona is available globally and applications can be carried out by trained and validated personnel from third parties as long as they fulfill the prerequisites. By allowing the asset owner to choose who would carry out the design and apply the wraps onsite (if those parties are qualified as per the standard), the operator has the flexibility to appoint the contractors best suited, depending on the specific requirements of a project. GP

|

| FIG. 6. The company’s pipe repaira application before being overcoated with an epoxy coatingh (immersion grade) for extra protection. |

NOTES

a Belzona SuperWrap II

b Belzona 1981 resin

c Belzona 1982 resin

d Belzona 1983 resin

e Belzona 9381 hybrid fiber

f Belzona 9382 consolidating film

g Belzona 1111 (Super Metal) two-part repair composite

h Belzona 5811 (Immersion Grade) epoxy coating

REFERENCES

- International Organization for Standardization (ISO) 24817:2017, “Petroleum, petrochemical and natural gas industries—Composite repairs for pipework—Qualification and design, installation, testing and inspection,” 2023.

- American Society of Mechanical Engineers (ASME) PCC-2 (Article 401), “Repair of pressure equipment and piping,” 2018.

- Alexander, C. and B. Francini, “State of the art assessment of composite systems used to repair transmission pipelines,” IPC 2006.

- Online: www.engineeringtoolbox.com

- Oharriz, O., “Pipelines: The composite solutions,” World Pipelines, January 2016.

|

Yusuke Nishi is a Senior Technical Services Engineer for Belzona Asia Pacific based in Thailand and has been with the company since 2011. Nishi is an experienced professional within the plant maintenance industry specializing in composite repair and protective coatings. He possesses in-depth technical knowledge in various areas of polymeric solutions with a focus on corrosion management and problem solving, gained from more than 10 yr of experience at Belzona.

Comments