Case study: Seal-less caustic circulation pump failure

A Saudi Aramco gas plant contains two (2 × 100%) lean caustic circulation seal-less pumps. The pumps are responsible for delivering the lean regenerated caustic with naphtha from the disulfides separator to the naphtha wash settler. The pumps are considered an essential component of the caustic regeneration loop that ensures removing the total sulfur from the natural gas liquids (NGL) products.

Pump design. The pumps are 178-hp seal-less magnetic drive pumps with a rated flow of 294 gal/min (gpm) and a total differential head of 638 ft. The process fluid is totally contained inside the pump containment shell and depended on to remove the generated heat through internal lubrication paths. Therefore, the slightest restriction to the lubrication flow paths will jeopardize the condition of the pump internal parts, resulting in a catastrophic failure. Additionally, the fluid runs between the inner magnet, the containment shell and through the shaft holes to the rear of the pump shaft, where it returns to the pump’s suction through the thrust balance hole in the impeller (FIG. 1)

|

| FIG. 1. Magnetic drive pump lubrication flow regime. |

The pump shaft connected to the inner magnet is rotated by the action of the magnetic flux circuit between the inner and outer magnets. The outer magnet is coupled to the driver motor through another shaft to transmit the rotation to the inner magnet.

Background. Within normal operating conditions, the pump was tripped due to a motor thermal overload fault signal. All process conditions were checked and found to be within normal parameters. The pump was later started again and immediately tripped on a stalled motor fault signal.

It was decided to remove the pump for dismantling and internal inspection. Major findings included:

- Excessive rubbing occurred between the impeller front cover and the pump casing, as well as thinning on the impeller shrouds. This is an indication of high thrust movement.

- The rear thrust pad, thrust washer and sleeve bush were not found in place. The silicon carbide bearings were found to have completely failed and their traces were found inside the pump casing (FIG. 2).

FIG. 2. Rear bush housing assembly (bush carrier) with damaged thrust pad corrosion/erosion impact. Additionally, signs of chemical attack (corrosion) were found in the front NDE titanium bush housing assembly.

Investigation. Based on the inspection findings listed above, operational trends, caustic lab sample analysis and metallurgical analysis, the following conclusions were reached:

- Material analysis showed that grains of the titanium sleeve bush were colored blue, consistent with the newly introduced process catalyst in 2019. This was considered a sign of a corrosion reaction. It is suspected that the catalyst filled the standby pump when it was not in operation—the pump would have been unable to disperse the liquid. The product would have then attacked the front sleeve bush, as this is mounted in the casing volute, whereas the rear sleeve bush is in a less accessible area of the pump.

- Occasionally, the process is subjected to high caustic concentration. Material analysis shows that there should be an accelerated rate of corrosion of the titanium sleeve bush carrier in instances where the pump is exposed to higher (40%–50%) caustic concentrations.

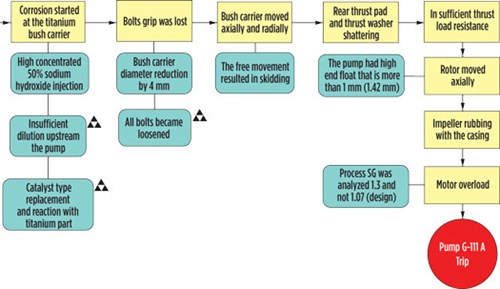

As shown in FIG. 3, it is suspected that corrosion and the loss of the titanium sleeve bush circumferential were enough to allow the bolts to loosen their grip between the bush carrier and holder. Consequently, all of the bush carriers became free to move radially and axially, leading to the thrust pad and thrust washer silicon carbide to shatter.

|

| FIG. 3. Proprietary processa identifying the casual factors and sequence of a pump trip. |

The failure of the rear thrust pad and thrust washer (active bearing) increased the negative thrusting and axial movement of the whole rotor towards the pump casing. This resulted in heavy wear on the casing, impeller and radial bush failure.

Recommendation. It was concluded that the impact of the intermittent 50% caustic concentration and the new catalyst type corroded the titanium part, resulting in thrust bearing failure.

The vendor confirmed that the use of titanium is not a common selection, but the request had been made by the customer during the project design. Additionally, it was noticed that the other pump components that are made of duplex stainless steel did not experience any corrosion attack.

From these findings, vendor experience and the corrosion chart, it was recommended to upgrade the bush housing material upgrade to duplex stainless-steel material. GP

NOTES

a TapRoot

|

FAISAL AL DOSSARY is a Consulting Services Department Engineer for Saudi Aramco. Mr. Al Dossary’s experienced ranges from reliability programs, such as vibration monitoring and condition monitoring, to troubleshooting, equipment design improvement, project management and commissioning. He graduated from Oregon State University with a BS degree (honors) in mechanical engineering. The author can be reached at Faisal.dossary.32@aramco.com.

|

DHEDAN AL DOSSARY is a Maintenance Reliability Engineer for Saudi Aramco. He joined the company in September 2018 as a Reliability Engineer in the Wasit Gas Plant Department. As a Plant Reliability Engineer, he specializes in rotating equipment condition monitoring, commissioning, overhauling, troubleshooting and conducting reliability improvement studies. Mr. Al Dossary’s experience lies in different mechanical sectors, such as static equipment and engineering design, reciprocating compressors pumps, steam turbines, centrifugal pumps and compressors. He graduated from King Fahd University of Petroleum and Minerals with a BS degree (honors) in applied mechanical engineering. The author can be reached at dhedan.aldossary@aramco.com.

Comments