New in Gas Processing Technology

A. Blume, Editor

Electro-pneumatic valve positioner for gas applications

|

ControlAir LLC, a manufacturer of precision pneumatic and electro-pneumatic control products, recently announced the expansion of the Type 2000 Electro-Pneumatic Valve Positioner series to include worldwide safety approvals for use with natural gas when paired with the Type 950 Explosion-proof I/P Transducer.

The Electro-Pneumatic Valve Positioner mounted with ControlAir’s Type 950 Explosion-proof I/P Transducer is CSA, FM and ATEX approved for use with natural gas. The natural gas package (CA2022/2023) was designed as an option to deliver safe, stable and accurate control of rotary and linear valves in applications using sweet natural gas in hazardous environments.

The CA2022/2023 Electro-Pneumatic Positioner is a NEMA 4X (IP 66) enclosure that provides rugged resistance to severe industrial environments and is designed for both intrinsic safety and explosion-proof operation.

Natural gas extraction and transport applications in remote locations often do not have access to compressed plant air for operation of pneumatic valve actuators. In this case, natural gas from the pipeline is used to supply the inlet pressure to the CA2022/2023 Electro-Pneumatic Valve Positioner that accurately positions the valve stem proportionally to the command

of the input signal received.

Advanced circuitry includes electronic feedback control for vibration protection and highly accurate output. The high accuracy of the CA2022/2023 Electro-Pneumatic Valve Positioner is reported to

surpass most control system requirements. The positioner typically consumes 0.05 sft3/min of air in operation, making it less costly to purchase and operate.

The CA2022/2023 Electro-Pneumatic Valve Positioner is suitable for a number of natural gas extraction and transport applications.

Q.E.D Environmental Systems gets CSA certification for gas analyzers

|

Q.E.D Environmental Systems announced that its LANDTEC BIOGAS 3000 and BIOMETHANE 3000 fixed gas analyzers have received certification by the CSA Group. The CSA safety mark signifies that the equipment has been independently tested for compliance with North American and Canadian safety standards.

Canadian and North American regulations and codes governing the use of electrical or battery-powered equipment in a potentially hazardous location require the use of certified equipment. Public health and safety officials, including fire marshals and electrical inspectors, have the authority to disapprove an installation or the use of equipment without the appropriate safety certification.

The BIOGAS 3000 and BIOMETHANE 3000 analyzers are AC-powered products that measure biogas and landfill gas and can be installed in potentially explosive areas. The CSA certification ensures that the equipment can be safely used and will not cause an explosion.

Q.E.D redesigned the equipment to meet specific territory standards, including ensuring that component temperatures do not exceed limits that could ignite a gas and will not result in any sparking that could contain enough energy to cause ignition. Other requirements include creepage limits, component clearances to avoid short-circuits, and NEMA 4X integrity testing for weatherproofing.

The equipment was then submitted to the CSA Group, which reviewed the product for compliance against recognized standards. Q.E.D received the CSA Certificate of Compliance, which is good for the life of the product, provided the equipment is installed and regularly maintained in accordance with the operating manual.

In addition to receiving CSA certification, the two analyzers also have ATEX and IECEx certifications for use in potentially explosive atmospheres.

Pipeline foam reducer prevents foam ingress to plants

|

Amine Optimization Co. has introduced a new, advanced technology for reducing foam in pipelines. The AO-21 Pipeline Foam Reducer was specially created to prevent foaming agents from entering processing plants.

Foaming contaminants usually enter plants after pipelines are pigged, causing contaminant ingression and severe upsets in process units, such as amine and glycol units. The AO-21 Pipeline Foam Reducer is thermally stable to eliminate any possible interaction with the process, and has a unique molecular architecture that is highly efficient for pipeline applications.

The AO-21 Pipeline Foam Reducer is the latest innovation in Amine Optimization’s advanced products for amine units. Each antifoam for amine units eliminates foaming with minimum dosage and no foam return if accidentally overdosed. All products are fully compatible with all generic and proprietary amine blended solvents. They are also thermally stable to eliminate possible interactions with the process.

First Super-B train trailer for LNG transport

|

Canada-based Cryopeak LNG Solutions Corp. has developed the first-ever “Super B-train” LNG hauling trailer to optimize small-scale LNG transportation in Canada. The trailer is designed to be interoperable across Canada and is in full compliance with Transport Canada rules and regulations for the transportation of LNG.

The development of the trailer is in line with Cryopeak’s business objective of providing natural gas solutions to companies and municipalities that are seeking to transition to an environmentally sustainable and competitive fuel source.

The new Super B-train trailer is a breakthrough technology designed to have 70% greater capacity than standard trailers operating in Canada.

Novel technology improves Mustang C2, C3 recovery

Honeywell announced that Mustang Gas Products LLC is using Ortloff GSP plus Retro-Flex technology from Honeywell UOP to improve recovery of ethane and propane at its Dover Hennessey cryogenic gas processing facility in central Oklahoma.

The Mustang plant marked the first global application of the Retro-Flex process, a new retrofit technology that improves propane recovery in both ethane recovery and ethane rejection modes for existing Gas Subcooled Process cryogenic plants, without requiring additional compression.

The facility is exceeding design recovery levels of 95% of ethane and 100% of propane in ethane recovery mode, and rejecting more than 95% of ethane while recovering more than 99% of propane in ethane rejection mode.

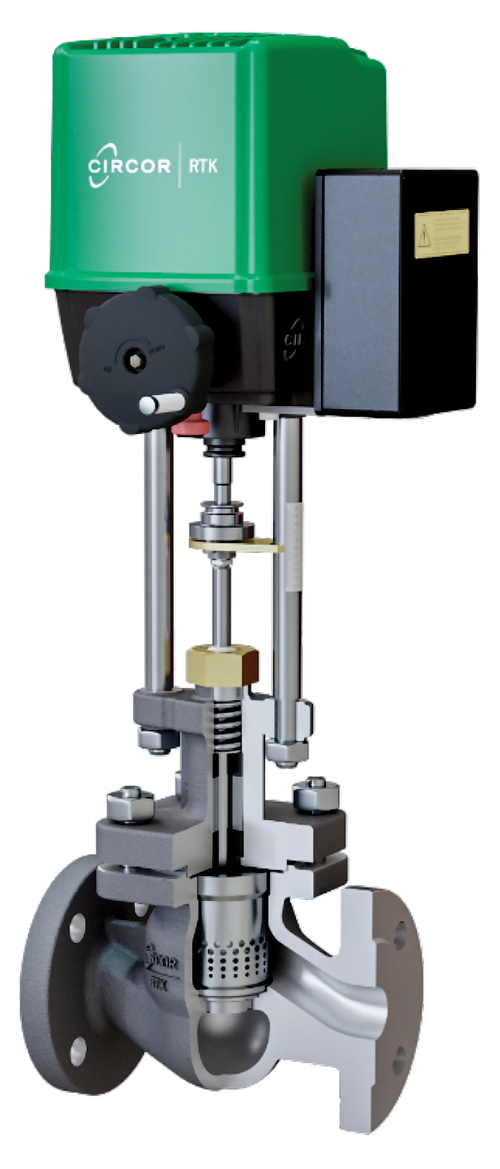

Circor introduces REflex control valve

|

RTK, a Circor International brand, recently introduced the REflex quick change seat control valve with REact 30 DC-PoP smart actuator, a flexible, all-in-one solution for noise reduction and high pressure drop applications.

The REflex control valve assembles and disassembles in four quick steps, without the need for special tools, accelerating maintenance by up to 85% for efficiency and cost savings. Additionally, tool-free seat exchange allows for quick adaptation to changing conditions. Featuring optimized, high-capacity flow paths and interchangeable trim, the two-way REflex control valve supports a variety of media and meets NACE standards for use with abrasive liquids and gases.

The REflex control valve is customizable for lower flow and higher pressure drop and is available in one or two stages, as well as in a range of sizes, pressure classes and end connection types. All REflex valves are available either as ANSI or DIN, ensuring that direct replacement is always possible.

The valves are said to be ideal for power, process, industrial, chemical, petrochemical, LNG, refrigeration technology, and oil and gas applications. They can be used for control and shutoff of liquids and gases, feedwater boiler filling, superheater startup, and as relief valves.

The REact 30 DC-PoP actuator equips the REflex control valve with smart valve technology to ensure system safety in any situation. When operating in normal conditions, the REact 30 DC-PoP’s high-efficiency, brushless DC motor can be adjusted to four separate speeds for energy savings and precision.

These systems can be interconnected for remote monitoring. In case of power failure, the two system-saving functions—the standard emergency closing unit and a power-off positioning module—smoothly opens or closes to a predefined safety end position. The automatic return to closed-loop control is possible without any external components or wiring, ensuring that the valve resumes normal duties when the plant returns to normal operations.

Linde selected for Greater Tortue LNG

Linde has been selected as LNG technology licensor for the second and third phases of the Greater Tortue Ahmeyim project, jointly developed by BP, Kosmos Energy, Société des Pétroles du Sénégal (PETROSEN), and Société Mauritanienne des Hydrocarbures et de Patrimoine Minier (SMHPM).

Greater Tortue Ahmeyim LNG, which will be operated by BP, is the deepest offshore project in Africa to date and is located on the maritime border between Mauritania and Senegal.

Under the terms of the signed master agreement, Linde will provide technology licensing services, based on the its MFC2 liquefaction technology. Linde will also manufacture and supply the related cryogenic coil-wound heat exchangers.

The Linde MFC2 liquefaction technology is both compact and energy efficient, making it well suited to offshore projects like Greater Tortue Ahmeyim LNG.

Comments