Perform transient analysis of a gas pipeline

M. A. Arce, ICA Fluor, Mexico City, Mexico

Natural gas pipelines are increasingly important pieces of infrastructure to help maintain the high momentum of gas production, especially shale gas. Many countries have developed wide networks enabling gas transportation to highly populated areas, where the gas is used for power generation and heating.

The transport of gas requires a different analysis than does the transport of liquids. Gas is more heavily impacted than liquids by changes in pressure and temperature, and this difference affects the flow behavior of gas vs. liquids under the same conditions.

For gas lines (both process lines and in-plant lines), there is a set of considerations for design that involves the definition of the ruling flow conditions as an isotherm or an adiabatic flow. These assumptions are settled to simplify the calculation process.

In long gas pipelines, however, these assumptions are unacceptable because the range of error is greater. A quick estimate is not sufficient to define the design of a gas pipeline. Fortunately, a wide range of computational tools exists to simplify the tedious calculations related to the design and projected operation of a gas pipeline.

Transient analysis. “Transient” implies the effect of time over the operational behavior of an industrial facility. In many ways, time is a variable related to the continuous pursuit of the steady state. When the system is changed in a way that impacts the steady state, the entire system will change until it reaches a new steady state. These transitions form the basis of study for a transient analysis.

To ease the design task, the most common method of performing an analysis is to consider a steady rate of consumption for each gas consumer. However, if the consumer’s behavior is unsteady, then the resulting flowrate will be uneven, and the consumer is more likely to experience difficulties using the pipeline network. Problems such as lower-than-expected flowrates, outages or even pulsation effects can occur.

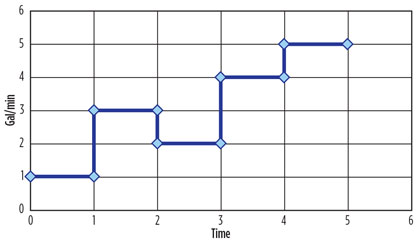

Consider the example of the design of a water distribution network system that supplies several users with even consumption. If the network design consideration is an average flowrate of 3 gal/min, then three users may be serviced; simultaneously, however, once four or more users are accessing the system, a serious supply problem will arise (Fig. 1). These situations can be avoided with the use of transient modeling, allowing for the reproduction of usage conditions that may be present over time.

|

|

Fig. 1. Example of consumption in a water distribution network with different |

Gas pipeline operation dynamics. Pipeline dynamics are described by a complex hydraulic model. Gas state conditions rely mainly on the relationship between three variables: pressure, temperature and volume.

Due to the intricate relationship of gas state condition variables, there are several problems involved in the dynamic analysis of a gas pipeline, such as:

- Line pigging. Occasionally, every gas pipeline requires a pigging procedure to clean the internal pipe walls to reduce disruption of the flow area. A transient analysis allows the frequency of this procedure to be predicted, and it also allows for the gathering of other useful information, such as potential places for liquid holdup, to determine the parts of the pipeline that will require frequent maintenance. For these studies, precise information on the gas composition, pipeline routing, elevation profile and weather conditions are required for different times of the year. Advanced simulation software can help determine these conditions.

- Startup logic sequence. A startup operation implies several actions on the supply side and at consumer points. As an example, the supply side requires valve adjustments to allow a controlled flow to reach a specified pressure along the length of the pipeline. At the delivery point, an appropriate pressure must be reached if there is an allowance for backflow.

- Line packing studies. This series of studies examines changes during normal operation, and it helps determine pipeline behavior. The most common cases are temperature variation and consumption variation.

- Temperature variation. Depending on the latitude location, ambient temperature and soil temperature vary. These variations directly affect the stream heat exchange in the pipeline. Environmental aspects are a potential source for other problems, such as condensation and hydrates formation. To perform a temperature variation analysis, a complete profile is required for the soil temperature and the projected weather behavior in different seasons and throughout the course of a day.

- Consumption variation. The consideration of a steady rate of consumption is an ideal condition that will not necessarily last. Gas pipelines deliver product to energy production plants that use combined cycles or thermogeneration systems that require natural gas for operation; as a result, the volume of supply sent through gas pipelines is dependent on the rate of gas consumption for electricity generation.

- Safety shutdown studies. Emergency shutdowns are a special situation where pipelines, or any of the attached facilities, present undesirable conditions, such as high pressure, gas leakage or fire. In such an event, the facility is required to transition to a safety condition. Safety shutdown studies test the automation controls under undesirable conditions and final conditions.

For these studies, the shutdown procedures and facility characteristics (i.e., pipe/equipment sizing, valve characteristics, etc.) must be known. With these verifications come a set of simultaneous actions to confirm that the desired safe conditions are reached in compliance with safety requirements: - Pipeline depressurizing studies. These studies examine pressure release for a section of pipeline due to different causes, allowing for the verification of depressurization time, depressurization temperature due to the Joule-Thomson effect, and also flowrates. A dynamic simulation can be used to understand operating conditions prior to depressurization, along with isolation procedures for a sudden or programmed blockage.

- Antisurge protection. When a facility is provided with centrifugal compressors, it is important to verify the capacity and behavior of the complete pipeline system for conditions and possible changes that could cause a surge situation, along with how the system will react in such situations.

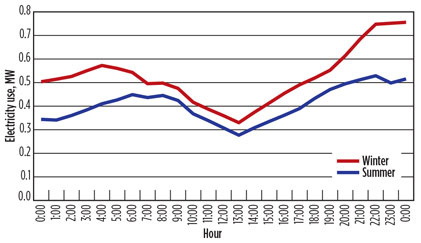

Variations in electricity consumption. An analysis of electricity use requires information about the end user. End users can be classified as industrial or domestic/commercial, with marked differences in consumption behavior. Residential consumption is variable, and, because electric grids that serve residential areas are so large, the total volume of gas needed to meet demand can be difficult to predict (Fig. 2).

|

|

Fig. 2. Residential electricity consumption varies by season, temperature swings |

A series of in-progress studies is seeking to classify peak electricity consumption and other variables in common industry terms. Such terms are useful in the modeling of a gas pipeline system's requirements. Also, most of the design and operation conditions can be verified through a transient analysis using this information to consider the effects of weather and consumption behavior in advance.

Within consumption variation, the most common cases for analysis are:

- Hourly consumption variation. As mentioned earlier, gas pipeline operation is related to human behavior. Consumption rates change throughout the day. The most common situation is that energy demand drops during working hours (approximately 8 to 18 hours) and, during nighttime, demand increases in each household. These changes can be mapped into a transient model, which can be useful in finding optimized solutions for meeting daily fluctuations in pipeline operation.

- Seasonal consumption change. In countries with extremely cold weather during the winter season, natural gas demand grows for heating and lighting requirements. In areas with extremely hot weather, air conditioning use increases during the summer. Understanding seasonal variation is important for finding optimal technical supply solutions (Fig. 2).

- Prospective consumption variation. Some pipelines are planned with the ability to increase transport capacity for a variety of reasons, such as the construction of a new, energy-intensive facility, or the expansion of a power distribution network. However, most of the time, the available solutions for such expansions should be reviewed in a dynamic model to avoid an interruption of the pipeline’s continuous operation. Adjustments, and even capacity increases, are assessed in advance to avoid technically difficult and expensive supply commitments.

- Abnormal consumption change. Abnormal consumption may be due to extreme weather changes, abrupt demand changes, net unbalances and other factors. Ideally, these undesirable situations should be managed without any damage to the system or unexpected outages.

In the creation and application of a transient model, the most important step is to have a clear view of the purpose of the study and the results being sought, regardless of what software is used. With a clear objective, the results will be useful for improving the design, operations, business plan and safety of a pipeline at a relatively low cost. GP

|

Mario Arredondo Arce is a senior process engineer at ICA Fluor, with 14 years of experience in oil and gas projects. He holds a BSc degree in chemical and industrial engineering, as well as an MBA degree. He is also a member of the American Institute of Chemical Engineers.

Comments