Smart LNG operations with a digitally integrated and enabled supply chain

LNG has become the fastest-growing global energy segment with massive investment in the LNG supply chain, especially in liquefaction capacity. However, global dynamics have created a worldwide supply/demand volatility that is projected to remain for the foreseeable future. To effectively respond to the market opportunities, LNG supply chain stakeholders must be agile and committed to reliable, operationally excellent, low-cost production. Foundational to these needs is the ability to leverage digital technologies and associated analytics, real-time situational awareness, and proactive, intelligence-based decisions.

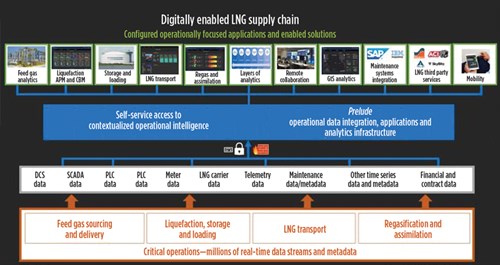

This article presents how leading LNG supply chain stakeholders are leveraging a digital infrastructurea across their LNG supply chain to provide self-service access to real-time, contextualized, operational intelligence in key areas of natural gas supply, liquefaction, LNG transport and regasification.

A foundational capability of such a digital infrastructure is the enablement of the subject matter experts (SMEs) to configure, evolve and manage “no-code” digital twinb templates that, when combined and operationalized, form an integrated digital replica of the physical LNG supply chain enabling scalability, manageability and intelligence sharing among the LNG supply chain community.

Supply chain risk mitigation. Moving into the next decade, the global LNG market will be characterized by rapid growth and expensive, long-lead-time projects with geopolitical and pricing risk. TABLE 1 illustrates the massive growth of each segment of the global LNG market and the growing complexity and optionality, as well as opportunity and risk.

|

On average, about 20 MMtpy of capacity will be brought online in each of the following 4 yr, cumulatively adding 80 MMtpy of liquefaction capacity. Today, there are 126 LNG carriers on order that will transport LNG to a growing number of destinations. Regasification capacity will expand by an additional 126 MMtpy over the next few years to reach 1,060 MMtpy in overall capacity, including FRSUs. The growth in competition, capabilities, and options will exponentially compound the complexity and risks faced by LNG stakeholders. It will indeed be “survival of the fittest” in the global LNG marketplace.

LNG operators are mitigating complexity and risk by adopting new contract pricing indexing models; by transitioning to smaller, more modular trains; by adopting new LNG technologies; by installing flexible and efficient refrigerant drivers; and by investing in FLNGs and FSRUs for flexibility. However, even with these actions, LNG stakeholders will need to be agile, flexible and opportunistic and strive for operational excellence to safely reduce their OPEX and reduce lost opportunity costs.

An effective risk mitigation strategy that is often overlooked by the LNG community is leveraging operational and commercial data to become operationally intelligent with real-time, self-serve supply chain decision support capabilities. A critical success factor for LNG industry leaders will be leveraging modern digital technologies, such as a real-time data infrastructure, no-code digital twins and layers of analytics. Significant opportunity exists in the creation of a digitally enabled and integrated LNG supply chain with a new level of agility, flexibility, cost performance and operational excellence.

LNG supply chain segment challenges and opportunities. The LNG supply chain consists of four major components, each of which presents unique challenges and risks that can be mitigated by the use of an integrated operational data infrastructure and no-code digital twins.

A synopsis follows of the key challenges and opportunities in each of the four LNG supply chain areas, as well as the ways to address these challenges with real-time operational intelligence.

- Feed gas sourcing and delivery. Feed gas quality, supply, and custody transfer risks and issues can be mitigated by proactively identifying feed gas quality issues, changes in feed gas volume and pressure, predicting feed gas volume needed to meet forecasted 24-hr rolling total LNG production, and validating total daily volumes received against commercial receipts that are provided via a secure digital link between the feed gas suppliers and the LNG plant operator.

- Liquefaction, storage and loading. As the costliest and most operationally complex part of the LNG supply chain, the challenges and risks of liquefaction, storage and loading consist of improving asset reliability and performance, optimizing production to meet forecast LNG loadings (with a focus on energy efficiency), as well as safety and environmental compliance.

To address these challenges, a real-time operational data infrastructure can provide advanced energy management, asset performance management, and condition-based maintenance with real-time, proactive, exception-based operational intelligence.

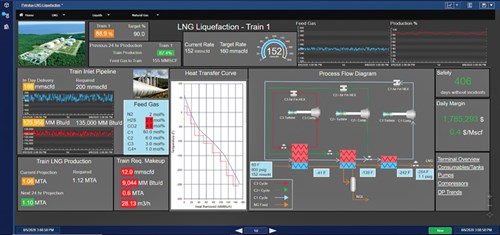

Some advanced capabilities of this digital approach include feed gas supply and LNG loading forecasting, refrigerant loop analytics and digital integration with LNG carrier operators to share, in near-real-time, LNG loading availability and LNG carrier arrival. FIG. 1 is an illustration of a configured smart liquefaction dashboard with key performance indicators (KPIs), conditional formatting and drill-down capability.

FIG. 1. A smart liquefaction display with operational intelligence. - LNG/FSRU transport. LNG/FSRU transport operators face numerous challenges, such as reducing the cost of operation, including energy, maintenance and logistics costs; meeting efficient class compliance and certification; complying with new IMO requirements in areas such as fuels, emissions and water handling; and reducing transit times with predictable, on-time arrivals and departures.

Leveraging a real-time data infrastructure, LNG/FSRU transport operators can address their unique challenges by providing real-time intelligence to the LNG/FSRU carrier from onboard systems and onshore oversight, support and scheduling operations. Class certification and compliance can be much more efficient and effective with digital integration between the certification company and the LNG/FSRU operator, including integration of asset performance management and condition-based maintenance data within a digital infrastructure that acts as a single system of record (FIG. 2).

FIG. 2. Smart LNG transport fleet overview with individual LNG carrier details, status and scheduled arrival time vs. planned arrival with conditional formatting. - Regasification and assimilation. After LNG is transported to receiving terminals, it must be returned to gaseous form. Regasification and assimilation operators rely on real-time operational intelligence to improve asset reliability and optimize performance, ensure efficient and predictable offloading, optimize energy efficiency, meet environmental compliance and provide predictable and efficient regasification and assimilation into natural gas transportation, storage and delivery systems.

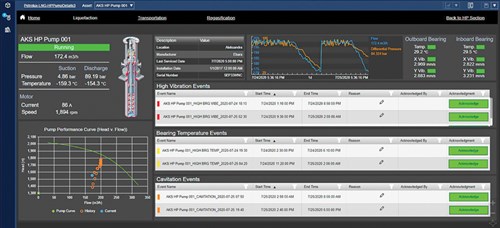

FIG. 3 illustrates a smart regasification display with KPIs, conditional formatting, asset metadata from the maintenance management system and critical process events. The performance curve for the high-pressure pump is an example of advanced asset performance management that includes the use of a no-code digital twin to enable layers of analytics, including descriptive, diagnostic and simple predictive analytics.

FIG. 3. Smart LNG regasification display provides real-time situational awareness into plant

and asset operations.

The digitally integrated LNG supply chain. Each LNG supply chain segment is tied together into a digital value chain. This value chain can be optimized by each stakeholder with digital technologies that permit selective and secure sharing of its digital LNG enterprise data. Such stakeholders can include operators in each of the four segments, as well as class certification companies, regulatory agencies, logistics companies and service providers. In many cases, the LNG operational stakeholder may be active in several of the LNG supply chain areas; for example, a regasification entity may operate a fleet of LNG carriers.

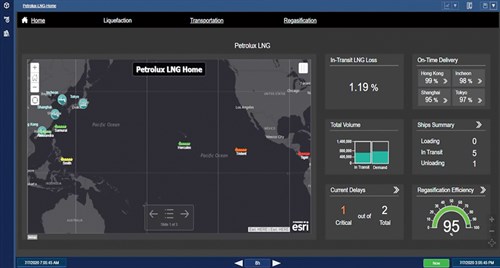

The ability to capture, abstract, normalize, contextualize and securely share operational data and real-time intelligence is becoming more commonplace in today’s connected world. This LNG supply chain’s digital community offers each operator an opportunity to leverage its data and intelligence to truly differentiate itself and provide significant value. FIG. 4 provides an example of a high-level LNG supply chain smart display.

|

|

FIG. 4. Smart LNG supply chain display delivers a 360° view of the entire LNG operation |

The data foundation of smart LNG operations. To understand the opportunity to leverage digital technologies across each segment of the LNG value chain, four key digital technologies and strategies will be introduced:

- Use of a real-time operational data infrastructurea

- No-code digital twinsb that are configured, evolved and maintained by SMEs with minimal IT support to abstract, normalize and contextualize operational data

- Configuration of LNG supporting applications and solutions in the infrastructure, either partially or fully

- Use of a “layers of analytics” strategy as a foundation for advanced analytics.

Real-time operational data infrastructure. The real-time operational infrastructurea is an agnostic, open, highly scalable and highly reliable technology specifically designed for critical operations with very large data volume, velocity and variability that enables:

- Integration of all operational data and metadata sources, using both tag-based interfaces and asset-based connectors with the associated asset metadata

- Historization and rapid retrieval of high-fidelity operational data, including the ability to store future data for forecasting

- Selection of either time-weighed or event-weighted averaging and totals for improved accuracy

- Integrate data from remote and mobile assets, some of which can go “dark” with inconsistent connectivity

- Standardization of diverse tag and asset naming into a consistent naming lexicon, using human readable names

- Governed access to different contextual views of the asset hierarchy and asset-level details

- Normalization of units of measure and time zones, including the ability to cast into different units of measure

- Gross error detection and enabling data validation, using rules and expressions

- Functioning as an analytical foundation by performing descriptive, diagnostic and simple predictive analytics

- Configuration and management by SMEs via no-code digital twin templates

- Configuration of common applications, such as energy management, asset performance management and condition-based maintenance

- Secure and governed real-time data sharing between LNG operators and stakeholders.

No-code digital twins configured and supported by SMEs. A digital twin is a replica of a physical asset, such as a pump or a compressor, comprising attributes, calculations, KPIs, empirical correlations and models of varying complexity. Contrary to the present marketing hype, digital twins have been around since the 1960s. However, today’s digital twins are dramatically more robust and sophisticated and range in their ease of use, approach and the ability to enable SMEs to leverage these technologies in a digital LNG supply chain.

Most digital twins require IT, data scientists, machine learning, model integration or programming to develop. They have a limited ability to scale, and struggle to address the anomalies of physical assets that have variability in vintage, model, make and level of instrumentation. Furthermore, real-time operational data and metadata—static information like make, model and location of equipment—typically reside as tags in DCS, SCADA and other systems with accessibility issues, limiting access to critical data that could potentially be leveraged by SMEs to gain insights.

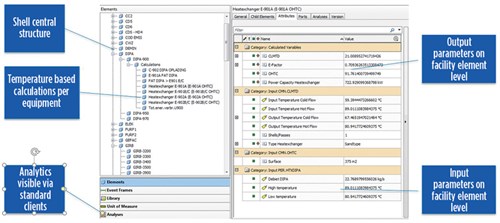

However, one digital twin technology2 uses a no-code configuration that SMEs can utilize in an agile, evolutionary way to create replicas of their LNG operations across the enterprise. These no-code digital twins rely on digital asset templates and can be combined to form a digital representation of physical LNG equipment, such as a refrigeration compressor/driver train, an entire liquefaction plant, an LNG carrier or a regasification unit. Using drag-and-drop capabilities, the no-code digital twins help SMEs configure replicas of their process operations and physical assets, such as pumps, compressors or entire liquefaction trains.

The use of no-code digital twins enables data abstraction into a standard lexicon while normalizing items like time zones and units of measure. They also aid with integration to other systems, such as the maintenance management systems and financial data systems, scheduling and others. Once combined, these digital twins form the foundation of a data directory and system of record for the LNG assets and even the entire LNG supply chain.

A key capability of the no-code digital twin is the enablement of an SME to develop a hypothesis about a process event, such as a compressor anomaly or failure. This is accomplished by enabling the SME to develop a new (or modify an existing) no-code digital twin and associated expression and test this hypothesis by running back into the operational history. Once satisfied with the new expression, the SME can then propagate the same event detection expression to all assets that use the same no-code digital twin template. This powerful capability allows comparison of like events as part of the diagnostic process and enables the continuous improvement of event analytics over time.

A real-world no-code digital twin operates onboard Shell’s Prelude FLNG, one of the largest floating production facilities in the world. Now anchored a few hundred miles off the coast of Western Australia, Prelude can produce natural gas and then liquefy it at sea, without the need for long pipelines to deliver it to gas processing plants onshore. The no-code digital twin technology monitors all equipment onboard the vessel, which combines upstream and downstream operations—from the giant chain winches in the hull to the gas wells under the sea. FIG. 5 is an example of the digital twin used on Prelude, as well as across Shell’s other operations.

|

| FIG. 5. Shell uses no-code digital twin technology onboard Prelude FLNG.2 |

The real-time data infrastructure on Prelude (FIG. 6) supports data integration of onboard vessel systems and the liquefaction facility. It also allows the configuration of a wide range of applications, such as asset performance management, advanced anomaly detection, energy management, condition-based maintenance, and environmental compliance and reporting.

|

| FIG. 6. Using a real-time data infrastructure with a no-code digital twin technology, Shell created a digital replica of its Prelude FLNG.2 |

Enabling configuration of LNG applications and solutions. Harnessing the power of a real-time data infrastructure with a no-code digital twin helps cut down the number of sources of common calculations, analytics, KPIs, totals and averages used pervasively across the LNG supply chain and also helps reduce errors and discrepancies.

SMEs who rely on this foundational digital technology can easily develop real-time calculations, such as efficiencies, health indexes, KPIs and descriptive, diagnostic, and simple predictive analytics. Such analytics allow for easy comparison of like assets, rollups of KPIs, period totals and other operational intelligence. Users can also leverage these digital twin templates to capture critical events, such as a compressor failure, enabling event diagnostics, alerts and notifications.

The use of time-weighted averaging and totals from underlying high-fidelity process data (vs. event weighting or averaging) further supports consistency and accuracy of the information and intelligence. FIG. 7 demonstrates how the data infrastructure and associated no-code digital twins can be leveraged in LNG supply chain applications and solutions.

|

| FIG. 7. Enabling the elimination of standalone LNG applications to simplify the LNG supply chain solutions. |

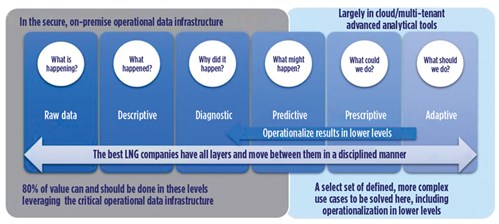

“Layers of analytics” strategy for advanced analytics. Terms such as advanced analytics, machine learning, big data and artificial intelligence (AI) appear pervasively in marketing literature today, often leading to confusion, failed projects and significant lost opportunity costs.

The most successful LNG operators leverage the value from analytics by first defining an analytics framework and the types of analytics, and then selecting market-proven, fit-for-purpose technologies. They use a “layers of analytics” strategy that takes into account the incremental cost vs. incremental value. These LNG operators start with descriptive, diagnostic and simple predictive analytics and move to more complex analytical methods. They eventually utilize all levels of analytics and move up to each level with discipline.

The foundation of this layered approach (FIG. 9) relies on the use of an operational data infrastructure to enable SMEs to configure descriptive, diagnostic and simple predictive analytics using formulas, empirical correlations and rule-based expressions. These lower-level analytics form the foundation for more advanced predictive, prescriptive and adaptive analytics that use machine learning and other advanced analytical methods. The lower analytical layers generally provide more than 80% of the value for about 20% of the cost vs. more advanced layers that rely on advanced analytical technologies, such as machine learning.

|

| FIG. 8. A “layers of analytics” strategy—disciplined evolution of analytical layers to deliver value. |

Upon utilizing all layers of analytics, it is important to feed back the results of the advanced layers to lower-level analytics as forecasts or targets to operationalize the advanced analytical output.

Recommendations. The LNG supply chain is facing numerous risks and challenges, from rapid growth fostering competition to geopolitical flux and pricing variability. Leading LNG supply chain operators will continue to aggressively adopt digital technologies that enable agility, flexibility, operational excellence, and proactive decision support to differentiate themselves from their LNG peers. These leaders are now leveraging digital technologies to digitally integrate internally, as well as externally with their counterparties, resulting in significant efficiencies and cost cutting, including reduction of lost opportunity costs.

Adopting an operational data infrastructure and the foundational no-code digital twins, simplifying traditional LNG applications and solutions, and supporting a “layers of analytics” strategy are the keys to successful digital transformation. The enablement of SMEs to develop, configure and evolve (with minimal IT support) the no-code digital twins is the secret to the digital LNG supply chain of the 21st century. GP

NOTES

a OSIsoft’s PI System functions as an integration, applications and analytics infrastructure for critical operations and enables SMEs to configure no-code digital twins to create self-serve access to contextualized operational intelligence and to support a “layers of analytics” strategy.

b No-code digital twins refer to the PI System’s Asset Framework, which includes an integration, abstraction and contextualization layer via data references to other data sources; a portfolio of 110 analytical functions optimized for time series data that leverage wizards for ease of use by the SME; event framing that enables configurable start and end of events with event analytics; and a configurable notification engine to trigger alerts via SMS or email, or to trigger work orders in a maintenance management system.

LITERATURE CITED

- International Gas Union, “2020 world LNG report,” and data from Rystad Energy.

- Van den Heuvel, P., “Real-time remote operations at Shell,” PI World, 2017.

|

CRAIG HARCLERODE is a Global Oil and Gas and HPI Industry Principal at OSIsoft. He has been focusing on digital-enabled business transformation addressing the dimensions of people/culture, as well as process reengineering leveraging the PI System in the areas of IIOT/edge, PI AF digital twins, layers of analytics and “big data” to deliver transformative business value. Mr. Harclerode’s 40-yr career has included engineering, operations and automation in supervisory, executive management and consultation roles at Amoco Oil, Honeywell IAC and Aspen Technology. He holds a BS degree in chemical engineering from Texas A&M University and an MBA degree from Rice University, and is a former Project Management Professional (PMP). He has published numerous articles and regularly presents at industry events around the world.

Comments