Gas processing news

B. Andrew, Technical Editor

GE in Romanian gas project

|

GE has been awarded an order from the consortium Duro Felguera—Romelectro (DF Energy) for core technology in a new combined-cycle power plant from Romgaz in Iernut, Romania. With a planned power generation capacity of 430 MW, the Iernut project is southeastern Europe’s largest gas project in 5 yr.

GE’s technology will be capable of generating the equivalent power needed to supply 1 MM Romanian households. In addition, the project is Romania’s largest public investment in conventional power in 20 yr, with a total investment of €268 MM from Romgaz.

The plant will feature four of GE’s 6F.03 gas turbines, two steam turbines and four heat recovery steam generators (HRSG) as part of an expanded scope of solutions from GE’s portfolio, following the acquisition of the former Alstom Power business. GE technology is expected to boost the plant’s gross efficiency to 56.4%—an increase of 18%—and reduce CO2 emissions by 38% compared to current levels.

The new combined-cycle power plant will be built within the existing gas-fired power plant site. Work will commence later in 2017, and the new plant is expected to replace the existing plant upon completion in 2019.

GE’s technology is anticipated to benefit the Romanian grid in several ways. In addition to flexible startup times of less than 15 min, the power plant will bring more stability to the grid by providing faster and more accessible energy reserves.

Also, the strategic location of the Iernut power plant—close to high-voltage lines connecting Romania’s different geographic regions—will enable energy providers to respond quickly to grid demand fluctuations in the region with minimal transmission and distribution loss.

Wood Group in Greek LNG project

|

Wood Group has secured a new FEED contract with Gastrade SA for the Alexandroupolis Independent Natural Gas System (INGS) offshore Greece.

The project, to develop a floating LNG receiving, storage and regasification unit (FSRU), will create a new natural gas gateway to the markets of southeastern and central Europe.

Wood Group’s subsea team will perform the design and engineering definition of the Alexandroupolis FSRU and its subsystems, which will support the final investment decision (FID) for the project. FID is planned for late 2017.

New LNG carrier to be equipped with Mark III Flex containment

|

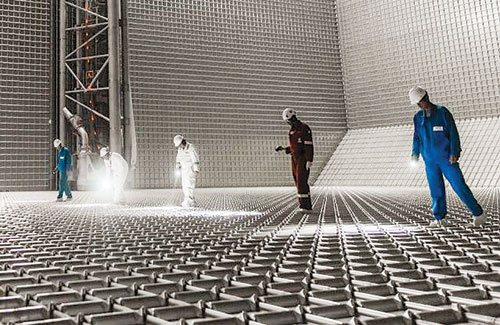

GTT has received an order from Hyundai Heavy Industries (HHI) to equip a new LNG carrier with its Mark III Flex containment system. Hyundai’s shipyard, based in Ulsan, South Korea, will build the 180,000-m3 vessel on behalf of Norwegian shipping company Norspan LNG XII AS (Knutsen). Delivery is scheduled for 2019.

At present, the Knutsen fleet contains 10 large-scale LNG carriers in service and one on order. All of the LNG carriers are equipped with GTT membrane containment systems. Mark III Flex, the technology adopted for this new LNG carrier, represents an evolution of the Mark range. It allows a boiloff rate of 0.085 vol%/d.

Gazprom to start gas supplies to China via Power of Siberia in December 2019

|

Gazprom has announced that it will start supplying natural gas to China via the Power of Siberia pipeline in late December 2019. According to Gazprom, the $400-B pipeline will transport natural gas from the Irkutsk and Yakutia gas production centers to consumers in Russia’s Far East and China. The pipeline will provide China with up to 38 Bcmy of natural gas supplies for up to 30 yr.

The construction of the eastern route pipeline will be complemented by the construction of the $12.7-B Amur gas processing plant. The plant will have a processing capacity of 49 Bcmy. Once completed, the plant will be Russia’s largest gas processing facility, and will constitute an integral part of natural supplies to China.

Syngas process for Uzbek GTL project

Topsoe’s synthesis gas technology has been chosen for Oltin Yo’l GTL, a 38-Mbpd GTL plant in Uzbekistan. The company will deliver proprietary equipment for two synthesis gas trains, each including autothermal reformers (ATRs), waste heat boilers, steam drums, CTS burners, refractory materials and HTZR target tiles.

Oltin Yo’l GTL will produce synthetic diesel, jet fuel, and naphtha from local natural gas.

In English, Oltin Yo’l means “golden road.” The project is anticipated to set Uzbekistan on a “golden road” of development. Site preparation work for the facility is already underway.

The GTL facility will be one of the most advanced energy plants in the world. Based on Uzbekistan’s rich natural gas resources, it will produce high-quality synthetic fuels that release fewer emissions when burned as transport and aviation fuel, thereby improving air quality.

Topsoe’s synthesis gas technology is the first fundamental step of Sasol’s Slurry Phase Distillate Process, which is the core process of the plant. Sasol Technology has been appointed the single-point licensor, and Hyundai Engineering Co. is the engineering, procurement and construction (EPC) partner.

Gazprom to fund Turkish Stream

Investment in the Turkish Stream gas pipeline project is estimated at $6 B, but the project can be implemented only at the expense of Gazprom, Deputy Chairman of Gazprom Management Committee Andrey Kruglov said at a press conference.

Gazprom does not intend to involve other entities in the Turkish Stream pipeline within the framework of the first thread, as the gas is intended only for Turkey. Shell or OMV may enter the second string, Gazprom said.

Gazprom commenced construction of the offshore section of the Turkish Stream gas pipeline along the bottom of the Black Sea on May 7. The first string of the pipeline will bring gas to Turkish consumers, while the second string will deliver gas to southern and southeastern Europe. Each string will have a throughput capacity of 15.75 Bm3/yr.

Golar, Delfin to develop Delfin LNG

|

Delfin Midstream and Golar LNG Ltd. have signed a joint development agreement (JDA) to develop the Delfin LNG project off the coast of Cameron Parish, Louisiana, utilizing Golar’s FLNG technology. The JDA will facilitate the financing, marketing, construction, development and operation of Delfin LNG.

Delfin LNG is the first and only permitted floating LNG (FLNG) export project in the US. Delfin LNG is a brownfield deepwater port requiring minimal additional infrastructure investment to support up to four FLNG vessels producing up to 13 MMtpy of LNG.

Delfin purchased the UTOS pipeline, the largest natural gas pipeline in the Gulf of Mexico, in 2014 and submitted its Deepwater Port license application in 2015.

Delfin LNG received a positive record of decision from MARAD on March 13. On June 1, Delfin received approval from the Department of Energy for long-term exports of LNG to countries that do not have a free trade agreement with the US.

Golar has successfully designed, financed, contracted, and built its first FLNG vessel, the FLNG Hilli Episeyo, which is scheduled to sail away from Keppel shipyard in Q3 2017. A second vessel of the same FLNG design, the FLNG Gandria, is soon to be converted subject to a final investment decision (FID) by the Fortuna project partners.

Golar is developing the Mark II next-generation floating liquefaction solution that is based on its Hilli and Gandria designs. The Mark II solution, as used at the Delfin LNG project, will have more than 3 MMtpy of liquefaction capacity and will be the lowest-cost liquefaction solution in North America.

It is expected that FID on the Delfin project will take place in 2018, with first LNG to be delivered in 2021–2022.

Lithuania signs first deal for US LNG

|

Lithuania’s state-owned gas trader, Lietuvos Duju Tiekimas (LDT), has signed a deal to buy LNG directly from the US for the first time. It expects to receive a delivery in the second half of August. The deal was made with a unit of Cheniere Energy and is part of Lithuania’s efforts to diversify its gas suppliers and reduce its reliance on Russia’s Gazprom.

LDT, part of state-owned energy group Lietuvos Energija, signed a deal last year with Koch Supply & Trading for LNG supplies throughout 2017. The LNG terminal at the Klaipeda port broke Russian Gazprom’s gas supply monopoly in the Baltic States when it came online in 2014, and now provides Lithuania with roughly half of its gas supply. Gazprom supplies the rest, but it can no longer charge monopoly prices.

Lithuania will store the LNG gas at its Incukalns underground gas storage facility, LDT said. Litgas, also owned by Lietuvos Energija, and Lithuanian fertilizer producer Achema import LNG through the terminal from Norway’s Statoil.

Compressor technology for offshore China

|

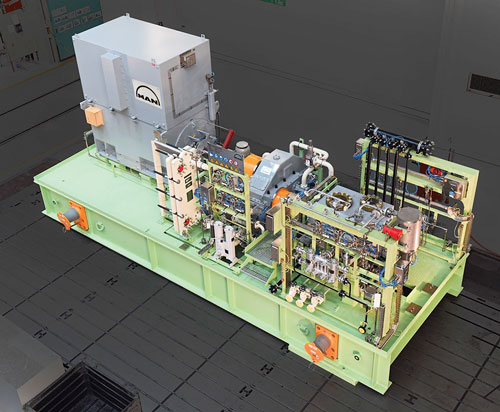

The Zhanjiang branch of CNOOC China Ltd. has commissioned MAN Diesel & Turbo to supply a total of six compressor trains for the Dongfang 13-2 Gas Fields Development Project in the South China Sea.

The compressor trains from MAN Diesel & Turbo Schweiz AG are to be used in gas reinjection and export on new platforms in the Dongfang 13-2 gas field, located in Yinggehai Basin of the Beibu Gulf, with an average water depth of approximately 70 m.

The total order comprises three wet gas and three dry gas compressor trains with intercooled barrel-type compressors, all driven by electric motors with a variable frequency converter. The wet gas compressor trains will be built as standardized and modularized upstream packages.

Today’s oil and gas industry is asking for best value solutions to tackle cost constraints, and for fast delivery times to start production as soon as possible. MAN’s standardized upstream packages address these requirements to the full extent without compromising on safety or reliability.

The modular approach of these packages makes it possible to cut costs and lead time considerably. The size and weight of the compressor packages are also reduced, resulting in additional benefits, especially for offshore application customers.

Sinopec, Linde to supply air gases to China

Sinopec, the biggest integrated refining and chemical company in China, and The Linde Group announced that they have established a €145 MM JV. Under the terms of the JV, they will supply vital industrial gases to local customers from key industries, such as petrochemicals, steel and electronics, within the Ningbo Chemical Industrial Zone in China’s Zhejiang province.

Sinopec Zhenhai Refining & Chemical Co. (ZRCC) and Linde will each hold a 50% stake in the newly formed Ningbo Linde-ZRCC Gases Co. Ltd. (Linde-ZRCC), the sixth consecutive JV between the companies. The agreement will see Linde-ZRCC acquire two existing air separation units (ASUs) from ZRCC and construct a third, for a combined 150,000 m3/hr of O2 capacity.

The new ASU, expected to come onstream in 2018, will incorporate Linde’s intelligent solutions for remote operation, diagnostics and analytics, as well as a modular design to increase efficiency, reduce energy requirements and enhance flexibility of production.

These three additional ASUs will double Linde’s production capacity for air gases in the Ningbo cluster and will be connected to Linde’s pipeline supply network across Ningbo. Linde’s Engineering Division will design and construct the new ASU. GP

Comments